The C.H.I.C.K® Program

The C.H.I.C.K® Program is the best-in-class hatchery vaccination service provided exclusively by Ceva specialists around the world to its customers and partners.

Thanks to quality-approved people, equipment, and processes, the Ceva Hatchery Immunization Control Keys’s program, known by everyone in the industry as the C.H.I.C.K® Program aims at having 100% consistently well-vaccinated birds.

Because Every Chick Counts

The C.H.I.C.K ® Program is implemented by qualified national teams of hatchery specialists in over a thousand hatcheries worldwide.

They provide training to hatchery operators and successfully install the most basic to the most sophisticated hatchery technology equipment.

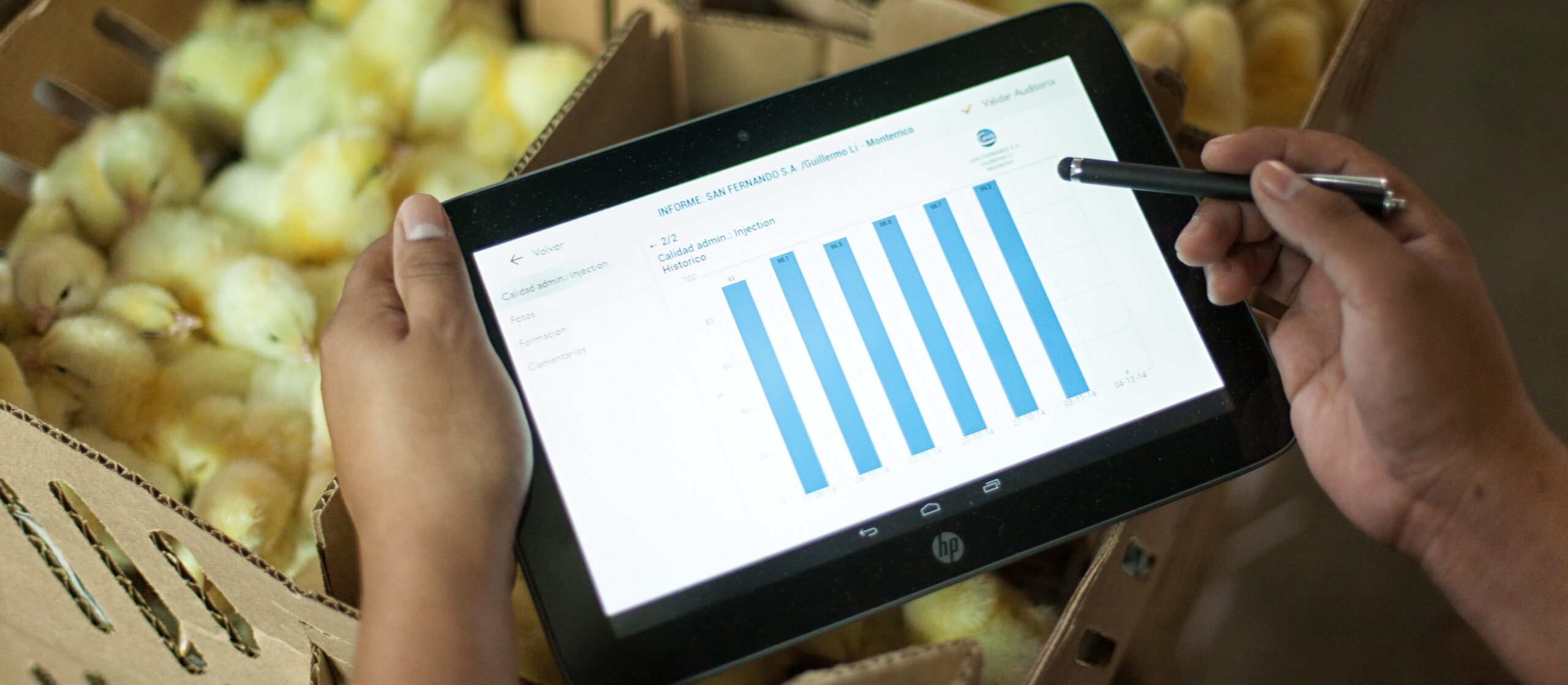

After installations, a continuous improvement plan is set up and monitored together with the hatchery management.

Our services for hatchery vaccination

In the C.H.I.C.K® Program, we make available a full set of procedures (SOP’s) to train and evaluate hatchery staff on the best practices for every stage in the hatchery vaccination process.

From storage of vaccines, vaccine mixing procedures, and administration quality through to equipment care, all steps are carefully covered for successful vaccination.

Preparation of vaccines

Dedicated procedures for the appropriate mixing of all types of vaccine

Accurate dosing

Ensure that a full dose of vaccine is applied to each chick

Operational control

Checking that equipment is correctly set up, working properly and cleaned.

Equipment maintenance

Ensuring correct installation and preventive maintenance.

Quality of administration

Random visual inspection of chicks to identify vaccination failures.

Our services for In Ovo Vaccination

When installing the Egginject® in ovo system in conjunction with LaserLife®, the Ceva teams offer a package of specialist services called the In ovo C.H.I.C.K. Programme.

With regular visits from our national teams of specialists, the In ovo C.H.I.C.K. Programme aims to ensure that 100% of eggs are correctly vaccinated whilst taking a holistic approach.

This includes monitoring factors influencing in ovo vaccination such as vaccine preparation, egg quality, embryo age diagnosis, process sanitation, vaccine dosage, hatchability and chick quality assessments, among others.

Preparation of vaccines

Dedicated procedures for appropriate mixing of in ovo vaccines.

Diagnosis of embryonic age

Key diagnosis for knowing the right time for in ovo injection according to the age of the embryo per herd.

Injection technique

Assessment of injection quality using the blue dye technique.

Vaccine dosage

A full dose of vaccine is administered to each embryonated egg.

Process sanitation

Regular tests to maximise hygiene conditions during the in ovo process.

Operational control

Checking that the equipment is correctly adjusted and in good working order.

Egg quality

Quality control of eggshells during storage before injection.

Hatching and chick quality

Key service at hatching to check that the performance of the in ovo process is as expected.

The C.H.I.C.K® is a worldwide Quality Program

In 2016, Ceva achieved a first significant milestone for the animal health industry when the successful implementation of this service program received independent Quality Recognition from the Bureau Veritas Group, an international testing, certification, and inspection company.

Thanks to our unique Quality Code of Practice, the C.H.I.C.K® Program services are based on four commitments to our customers:

>2,000

hatchery operators worldwide trained per year

65%

of hatcheries in the world audited

>2,100

Units of vaccination equipment serviced globallyper year

>8,000

Hatchery audits per year globally

200

Vaccination Services specialists

>1,200

Hatcheries visited

POULTRY

POULTRY