Ceva's liquid nitrogen logistics service in warehouses and hatcheries

The production and use of frozen vaccines, such as Marek’s cell-associated vaccines, in liquid nitrogen improves the quality, safety and efficiency of poultry vaccination. However, this also poses certain challenges for suppliers and customers.

Ceva’s LIquid NItrogen LOGistic (LINILOG) service helps maintain vaccine integrity and operator safety through constant monitoring of the vaccine freezing system in the warehouse and hatchery, including protective equipment and training.

Hatcheries: the first stage in the production process

Hatcheries play a strategic role for poultry companies, as the first stage in the production process. Cold chain management is essential to the success of vaccination.

By applying best practice in liquid nitrogen logistics, from warehouses to hatcheries, we aim to effectively immunise flocks with a preserved vaccine, supporting the entire production chain.

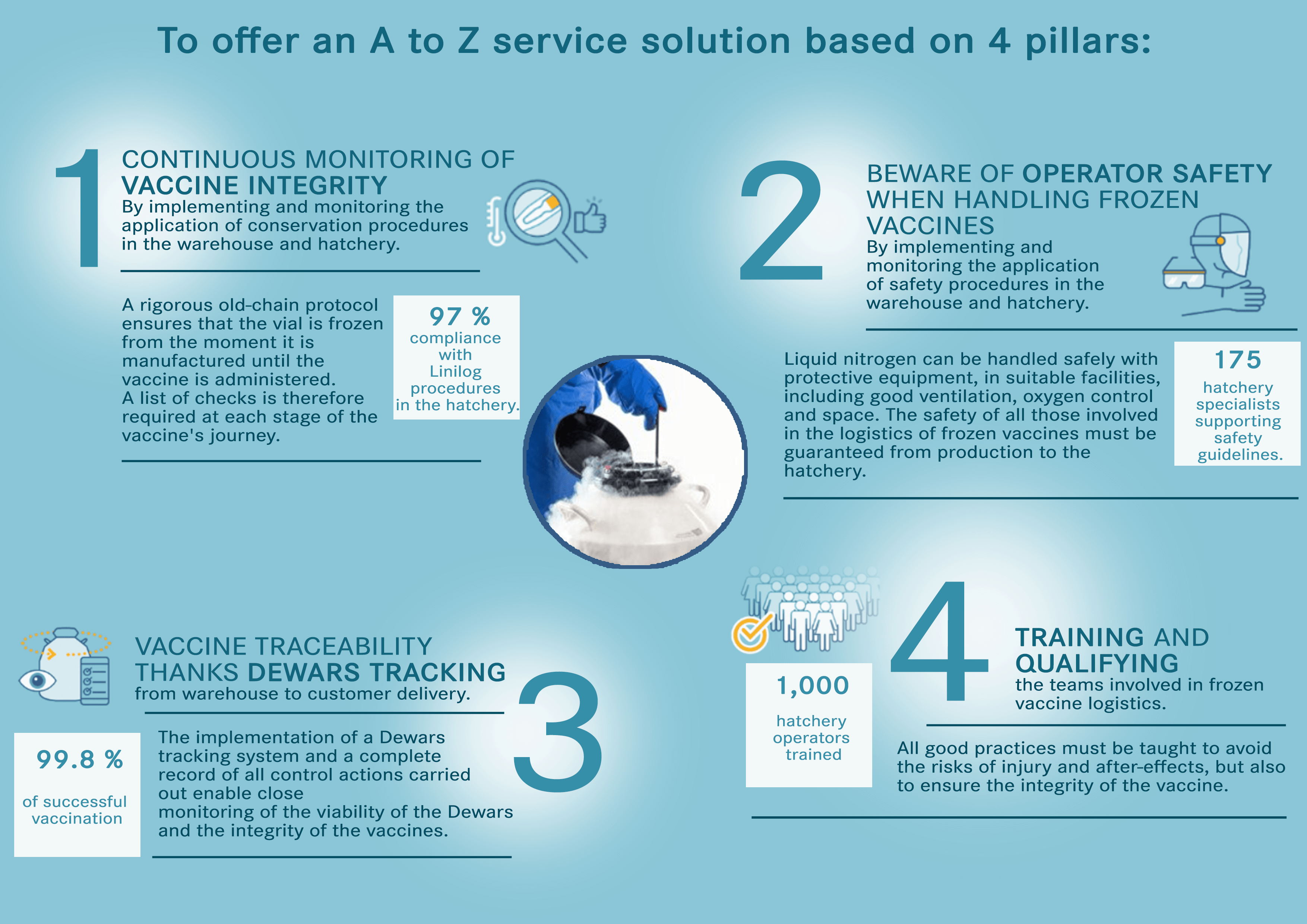

Offer an end-to-end service solution based on 4 pillars:

Continuous monitoring of vaccine integrity

Operator safety

Vaccine traceability

Training and qualifications

Cevas's Linilog programme is a global service standard for liquide nitrogen logistics

After 12 years of helping to preserve the integrity of frozen vaccines and human safety in warehouses and hatcheries, Ceva has created the Linilog Code of Good Practice and received quality recognition from an international third-party certification body.

Ceva’s head office has received quality recognition for providing all Ceva subsidiaries with training and tools for standardizing good practice in frozen vaccine logistics.

Quality recognition is now controlled by the Bureau Veritas Group at national level, for each candidate country.

Safety first and foremost! 3 essential elements to protect hatchery staff handling frozen vaccines

TRAINING

Anyone involved in handling frozen vaccines must be trained in safety practices and first aid procedures. It is essential to give people the keys to working safely, but also to reacting if they are involved in an accident or witness one.

VENTILATION

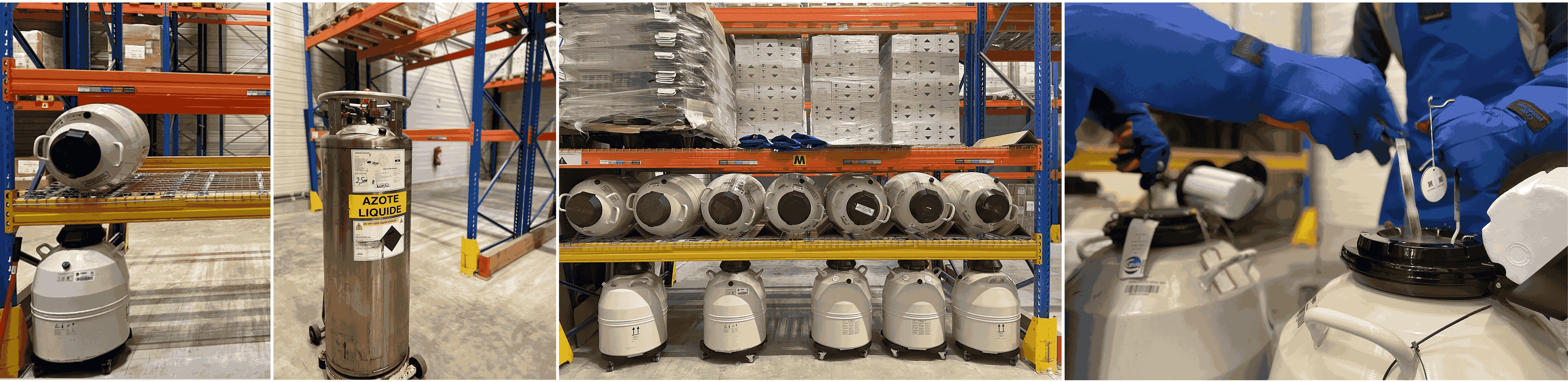

The liquid nitrogen in the Dewars is constantly evaporating. To avoid the risk of asphyxiation due to an increase in nitrogen in the air, a good ventilation system must be installed. Ideally, the room where the Dewars are stored is equipped with an extractor fan and the oxygen level is checked daily.

Use PPE

Clothing suitable for very cold temperatures must be worn when working with liquid nitrogen. Personal protective equipment (PPE), including a cryogenic apron, cryogenic grants, face shield, safety glasses, long sleeves and trousers, and fully enclosed footwear, must be provided for personnel. This equipment prevents frostbite to the skin or eye contact with liquid nitrogen in the event of a spill when handling liquid nitrogen.

Safety and Quality in Liquid Nitrogen Handling

In 2010, Ceva created the Linilog service (liquid nitrogen logistics) with 2 priorities: the safety of people and the integrity of vaccines. Ceva 175 Ceva’s hatchery specialists around the world are available to guide hatchery staff and monitor their liquid nitrogen handling techniques during their regular visits. They provide personal protective equipment, training and recommendations on the storage area and handling of dewar. Please do not hesitate to contact them if you have any questions.

In 2020, Ceva created the Linilog Quality Code and received quality recognition from an international third-party inspection body.

Linilog logistics platform in Tours!

Since December 2024, our first Linilog platform has integrated its latest module, deploying the Linilog liquid nitrogen logistics service for the storage and shipment of Ceva frozen vaccines.

This major advance enables us to ship this range of vaccines from France, with significant improvements in several key areas:

- Increased availability thanks to a stock dedicated specifically to Africa

- Reduced transport costs with shipments from France

- Optimization of the product mix, to offer a more complete solution tailored to different needs.

Key figures

+185

hatchery specialists around the world

99.8%

successful vaccine delivery

94%

compliance with Linilog hatchery procedures

1057

hatcheries visited around the world

POULTRY

POULTRY